52

53

MYTILINEOS HOLDINGS SUSTAINABILITY REPORT

2015

are some of the fundamental aspects of the specific policies on

product quality and safety applied by our subsidiaries in the Metal-

lurgy & Mining Sector as well as in the EPC Projects sector.

The industrial activities of METKA focus on the world-class man-

ufacturing for high-value added heavy and/or complex steel

fabrications for energy, infrastructure and defence applications.

Typically, these projects involve the use of the company’s sophis-

ticated computer controlled machining equipment and high qual-

ity fabrication capabilities.

Building on 50 years of experience in large-scale manufacturing

projects, the company’s state-of-the-art industrial facilities and

equipment offer significant competitive advantages to METKA,

particularly in terms of reliability and compliance with the most

stringent international quality standards. METKA is committed to

setting a high level of quality for customer satisfaction in every

stage of manufacturing. METKA’s high level educated and expe-

rienced personnel is ready to meet high level customer quality

requirements.

In the Metallurgy & Mining Sector, ensuring that mining and pro-

cessing of natural resources take place in a responsible and sus-

tainable way is at the core of our commitment to duly manage our

product. At the same time, this commitment represents a critical

stage that defines the level of the quality offered to our customers.

Key aspects of the management of our products are the techno-

logical upgrades of our machinery, the use of the strictest techno-

logical specifications and processes and the minimisation of the

solid and liquid waste from our production activities.

For the last 50 years, ALUMINIUM OF GREECE has embodied the

impressive evolution of the metallurgical sector in Greece, with

a know-how in industrial and commercial practices that is found

only among the world’s top metallurgical industries. The quality of

its products and the provision of technical support and customer

service are areas of continuous development.

An indicative example of the company’s efforts in this area is that,

in response to market needs and the requirements of competi-

tion, it invested in the construction of an airslip technology casting

unit in its plant’s Cast House. This investment brought an impres-

sive improvement in the quality of the end product and reduced

stock by minimising the unusable part of each aluminium billet,

thus increasing the plant’s production flexibility.

In addition, the company has obtained the ISO 9001:2008 Quality

Certificate for its products, while its quality control laboratory has

been accredited by Hellenic Accreditation System S.A. (ESYD S.A.)

in accordance with the requirements of the ISO 17025:2005 Inter-

national Standard, for the chemical analysis of bauxite, alumina

(both hydrated and calcined), and of aluminium and its alloys. This

accreditation concerns the Quality Management System of the

Laboratory and its technical competencies and overall adequacy

for carrying out tests in the areas for which it has been accredited.

Primary Aluminium

Annual Capacity

182 ktn

Refined Alumina

Annual Capacity

820 ktn

9.8 Strengthen Transparency

G4-SO3

In MYTILINEOS Group, promotion of transparency is driven by

a combination of three factors: (1) The Group’s corporate value

which refers to the “Principle of Integrity”, which is respected

across the Group’s Governance system and is implemented by

avoiding all transactions and contact with any third party which

may be guilty or suspect of encouraging conditions giving rise

to corruption; (2) the Group’s voluntary public commitment to

the 10th Principle of the UN Global Compact Initiative, according

to which “The Group works against corruption in all its forms,

including extortion and bribery”; and (3) the disclosure of the

Group’s Management Practice on strengthening transparency,

which is connected to the Group’s standing commitment to zero

tolerance of corruption and bribery.

2015 Highlights

• The Group completed the material for the 2nd edition of the

Professional Ethics Code, scheduled for publication in 2016,

providing for expanded coverage of the efforts for increased

transparency.

• In parallel, the Group continued to follow the procedures ap-

plied in the Purchases – Procurement Units of its subsidiaries,

with regard to checking the selection of business partners and

all types of transactions. In the context of these checks, no inci-

dents of corruption and bribery were identified.

9.9 Product Quality and Safety

MYTILINEOS Group complies fully with the national laws, the

international guidelines and industry standards applicable with

its activity sectors in relation with the design and production of

its products and the methods it employs for their promotion and

marketing. The Group places particular emphasis on the quality

of its materials, products and construction projects and applies

innovative production processes that improve the quality, safety

and environmental impacts of each product.

More specifically:

• the strict adherence to the laws and regulations,

• the principle that no product or construction project is released

from one production stage to the next unless the quality criteria

of the current stage have been fully satisfied,

• the strict application of the procedures under the EN ISO 9001

Quality Management System,

• the conduct of a Hazard & Operability (HAZOP) Study for oper-

ational risk analysis and the staffing of the Quality Control De-

partments with experienced personnel who are provided with

continuous training,

MYTILINEOS Group Social Contribution Programme 2016-2019

Corporate Values & Culture

• Support of Entrepreneurship

• Promotion of Arts & Culture

• Support of Education & Sports

• Improvement of local infrastructures

• Protection of the Environment

• Combatting serious diseases

• Protection of children's rights

• Bolstering Employment

• Fighting poverty

Business Activity

Social needs

Millennium Development Goals (UN)

Action Lines

Action Lines

Action Lines

Action Lines

Categories and percentage of significant Group products

for which health and safety impacts are assessed for

improvement.

Alumina

100%

Aluminium

100%

EPC Contracts

100%

Metal & Machinery Constructions

100%

1

4

7

8

9

17

15

20

23

24

25

26

27

29

30

28

21

10

11

22

12

13

5

2

3

18

16

6

14

19

1

4

7

8

9

17

15

20

23

24

25

26

27

29

30

28

21

10

11

22

12

13

5

2

3

18

16

6

14

19

G4-PR1

G4-SO5

G4-14

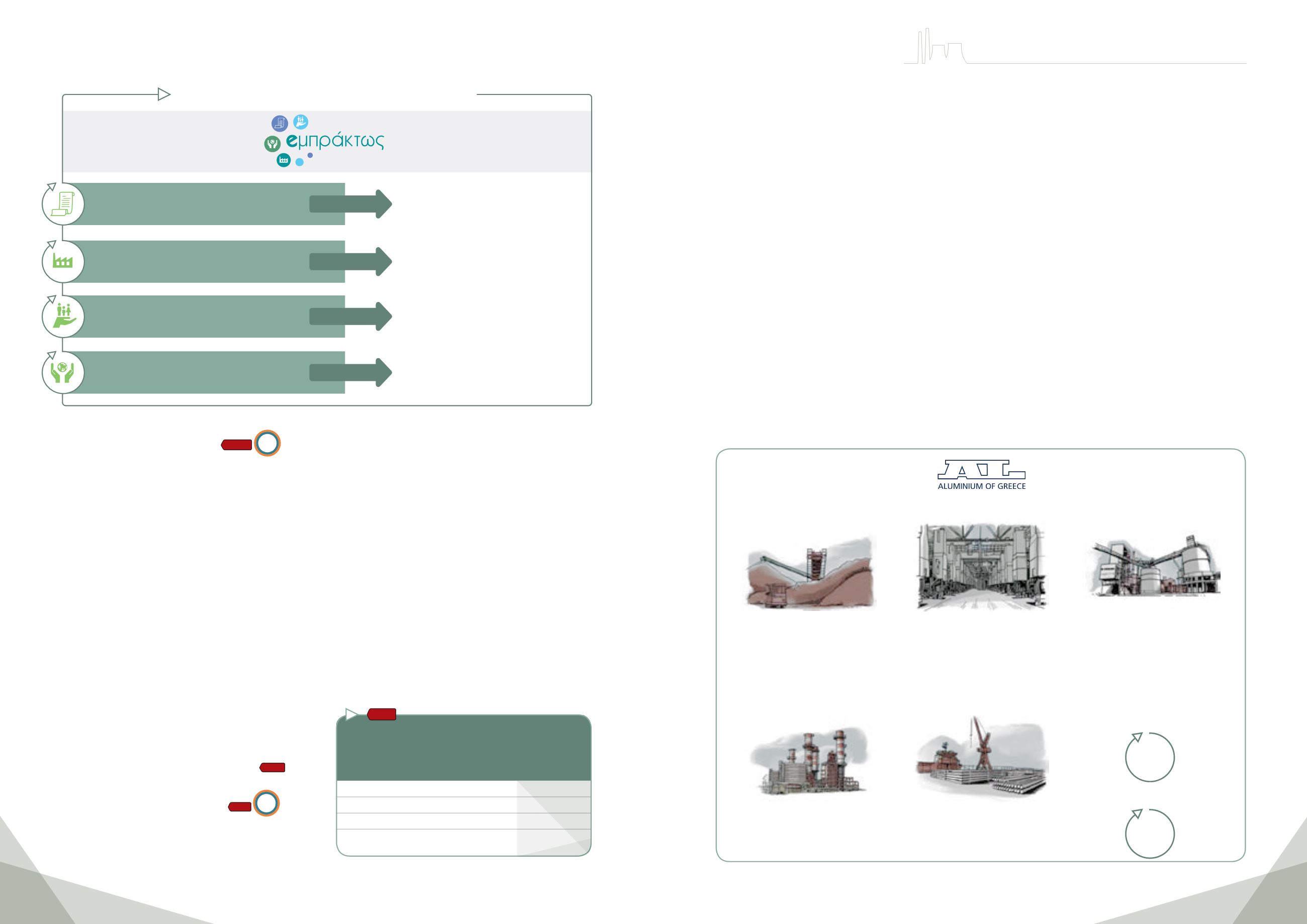

THE LARGEST VERTICALY INTEGRATED ALUMINIUM & ALUMINA PRODUCER IN E.U.

Bauxite Mines

• Second largest bauxite producer in Europe with

~700 ktpa of production capacity.

• Long life of mine underpinned by 11mt of

resources.

• Long-term off-take agreement with third parties

in Greece and abroad.

Aluminium Smelter

• ~182 ktpa of production capacity

• Established customer base

• Long-term off-take agreements provide security

of sales

Alumina Refinery

• Amongst largest standalone smelters globally

• Producer of 17% of total European Alumina output

~820 ktpa

• Sufficient capacity to cover internal needs for the

smelter and to export ~500 ktpa

• Long-term off-take agreement with global and

regional players

334 MW CHP

• On-site power and steam production offering

purchasing flexibility – Secured Electricity Supply

• Internal Steam production using Natural Gas

Port Facilities

• On-site port facilities for incoming raw materials

and outgoing finished products, minimising

logistical costs.