34

35

MYTILINEOS HOLDINGS SUSTAINABILITY REPORT

2015

8.6 Water

G4-EN8

The total volume of water withdrawn required for the Group’s ac-

tivities in 2015 stood at 164.8 million m

3

, down by 0.8% from 2014.

This reduction is mainly due to the restriction by 2 million m

3

of the

volume of seawater withdrawn for use in the cooling systems of

the Group’s heavy industry plants. In detail:

Regarding the seawater used in the cooling systems of the Com-

bined Heat and Power (CH) plant of ALUMINIUM OF GREECE, in

addition to the strict compliance with the relevant provisions of

the laws determining the framework for preventing any envi-

ronmental impact, the company commissions, on an annual

basis, an authoritative organisation (Hellenic Centre for Marine

Research - HCMR) to conduct of a research study to monitor the

status of living organisms (benthic biocoenoses, with emphasis

on thermophilic species) on the Antikyra Gulf seabed.

Finally, the quantity of water reused or recycled in the Group’s

activity sectors in 2015 stood at 4.53 million m

3

(corresponding

to 2.7% of the total volume of water withdrawn) . Of this

total quantity, 99.8% concerns water recycled/reused in the En-

ergy Sector. More specifically: (a) The utilisation of 4,508,422 m

3

of seawater, from the cooling systems of the Combined Heat

and Power (CHP) plant of ALUMINIUM OF GREECE, by the Ag.

Nikolaos thermal power plant of Protergia, and (b) the recycling

of 19,539 m

3

of liquid waste from the Heat Recovery Boiler of

KORINTHOS POWER S.A. (a subsidiary of Protergia).

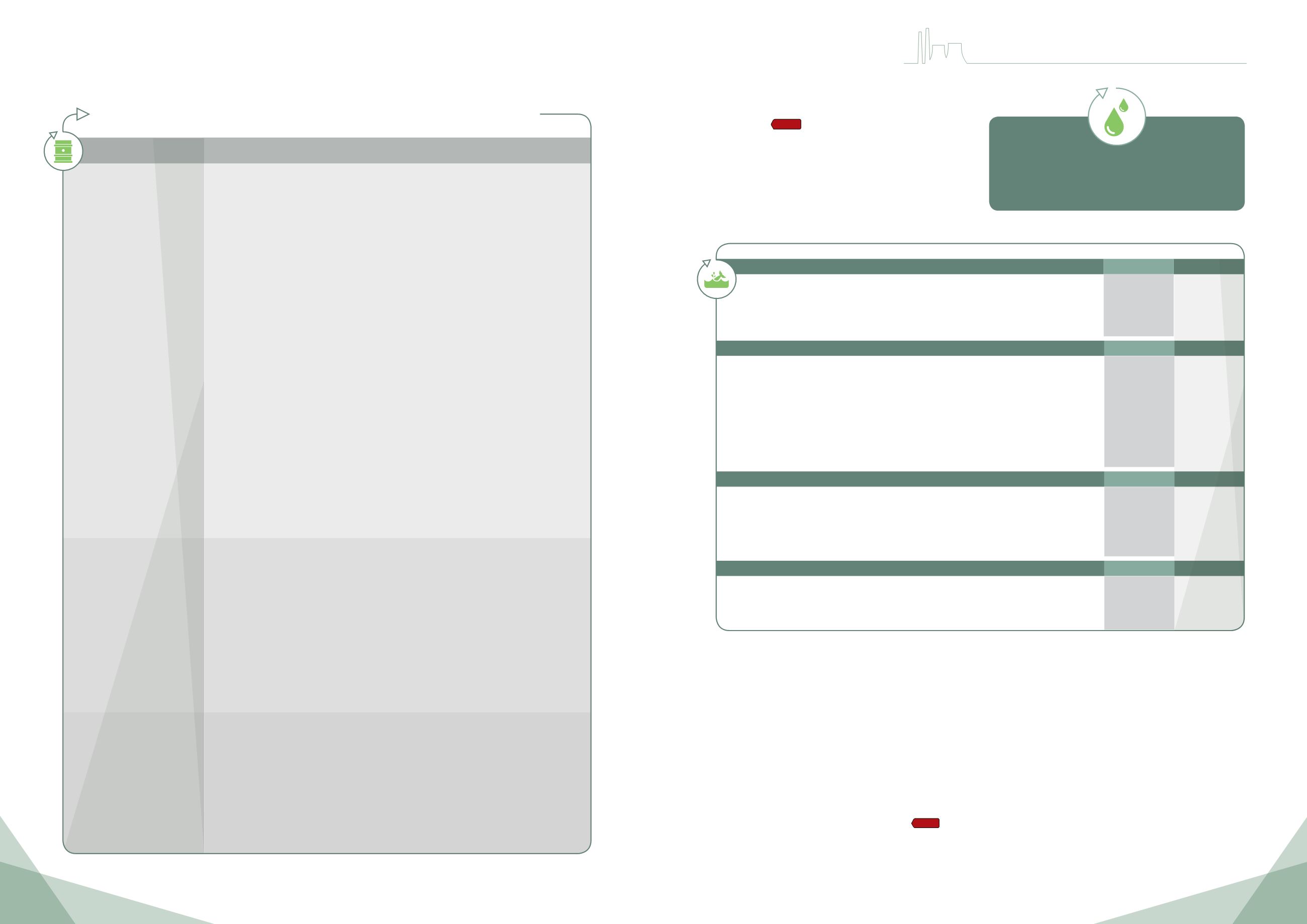

Total water withdrawal from surface waters (sea) (m

3

)

2014

2015

Down 1.3% from 2014.

Volume of seawater used in the cooling systems of the Combined

Heat and Power (CHP) plant of ALUMINIUMOF GREECE. The limit on the volume of seawater

withdrawn annually is determined by the Water Resources Management Directorate of the

Sterea Regional Administration.

161,733,577

159,609,769

Total water withdrawal from groundwater sources (m

3

)

2014

2015

Up 3.2% from 2014.

Volume of industrial service and drinking water used primarily

to meet the manufacturing/processing, energy and water supply needs of the Group’s

industrial facilities. Of total volume, 99.1% is obtained from a network of 17 drills, owned

by ALUMINIUM OF GREECE, which the company operates in the broader region around

its plant, in strict compliance with the provisions of the Water Resources Management

Directorate of the Sterea Regional Administration.

4,997,097

5,159,676

Total water withdrawal from public water supply utilities (m

3

)

2014

2015

Down 41.2% from 2014.

Volume of water from municipal reserves and public water

supply utilities used to meet the needs of the Group's buildings and primarily industrial

facilities, as e.g. happens in ALUMINIUM OF GREECE, which uses the quantity of water

attributable to the Metallurgy & Mining Sector and coming from the Athens Water Supply

and Sewerage Company (EYDAP - Mornos River Connection), exclusively for industrial

service use.

152,555

62,897

Total utilisation of stormwater (m

3

)

2014

2015

Up 16.6% from 2014.

Rainwater collected directly in a special reservoir configured in the

area of a disused mine, used by DELPHI-DISTOMON.

6,000

7,000

Group policy on the responsible management

of water:

G4-EN10

Quantity

m

3

/year

Destination

Quantity of water discharges, including treatment

method

Metallurgy & Mining

Sector

159,609,769

From the cooling process of

the Combined Heat and Power

(CHP) plant

Discharge to

the sea

(determined by

legislation)

pH: 8-8,2

Temperature: 22,3

ο

C

656,280

Wastewater, including

rainwater, measured at the

point of exit from the primary

treatment facilities

Discharge to the

sea (determined by

legislation)

Primary treatment (Settlement of floating particles,

filtration of supernatant fluid, chlorination, discharge)

pH 25

o

C with temperature compensation: 7,96

Chlorides - mg/l: 256,67

Fluorides - mg/l: 1,80

Biochemical Oxygen Demand (BOD5) - mg/l: 3,10

Chemical Oxygen Demand (COD) - mg/l: <7

Total Solids (103-105

o

C) - mg/l: 844,17

Total Suspended Solids (103-105

o

C) - mg/l: <25

Sulphides- mg/l: 0,05

22,159

Wastewater from the mining

process

Subsoil

No particular processing. This waste is water (from

licensed drills or water collected in underground

mining sites) used in the mining process, which

with the addition of inert bauxite or limestone dust

(depending on the particular mining activity), becomes

a liquid mix that ends in the aquifer.

3,500

Wastewater from mining site

workshops

Watering of

rehabilitated areas.

Cleaning of liquid waste from sites using a system of

filters (sand - active carbon). The water obtained by

this process is suitable for irrigation (site landscape

rehabilitation) or reuse in the production process.

Chemical tests show a BOD<5 (with the maximum

limit being 10).

Energy

Sector

52,040

Industrial service water in the

electricity production process

43,6%: Disposal to

a MotorOil liquid

waste treatment

plant

56,3%: Disposal by

closed pipeline to

the liquid waste

treatment plant of

ALUMINIUM OF

GREECE

The amount of the industrial service water intended

for disposal to Motor Oil undergoes treatment for

ph regulation (must be from 6.5 to 9), as well as for

temperature regulation (must be <65

ο

C.).

EPC Projects Sector

300

Water from Hydraulic Tests in

Construction Sites

Rainwater

collection network

& disposal for use

in irrigation.

Treatment in the Project's Biological Treatment

Facilities

52.000

Water from chemical cleaning

in Construction Sites

External licensed

Biological

Treatment

Facilities.

Temporary storage in a site tank for thermal load

balancing

Management of liquid waste and water discharges of the Group's activity sectors