26

27

MYTILINEOS HOLDINGS SUSTAINABILITY REPORT

2015

1

4

7

8

9

17

15

20

23

24

25

26

27

29

30

28

21

10

11

22

12

13

5

2

3

18

16

6

14

19

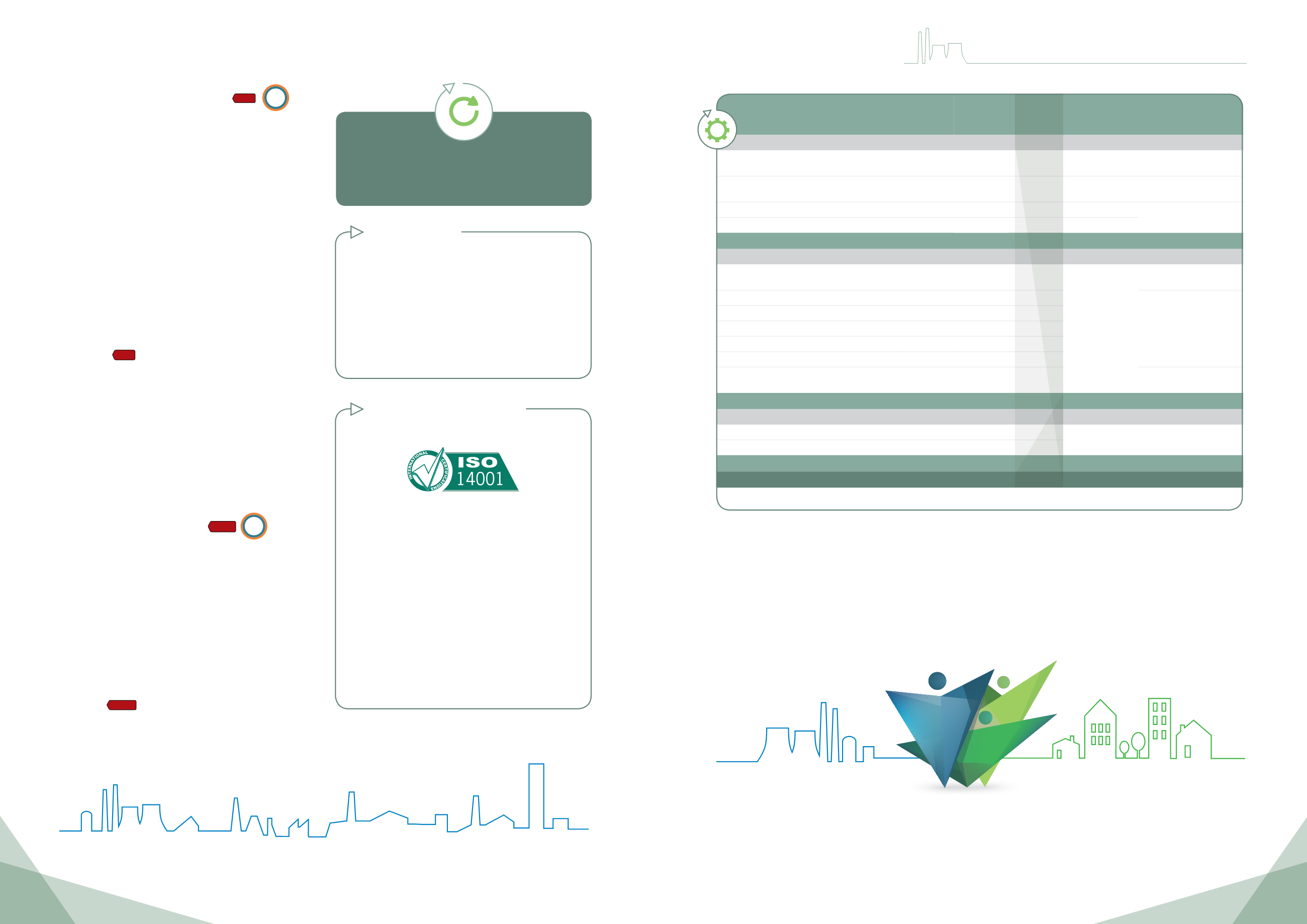

METALLURGY &

MINING SECTOR

2013

2014

2015

Measurement

Origin of supplies

Type and weight of Raw Materials (tonnes)*

Bauxite

1,830,398

1,830,996

1,833,201

Direct measurement

Internal & External

sources

Anhydrous alumina in electrolysis

326,985

332,656

345,587

Direct measurement

Internal sources or

production

Alloys

1,853

2,057

2,473

Direct measurement

External supplier

Other metals from third parties

322

44

0

Direct measurement

Subtotal (1)

2,159,558

2,165,753

2,181,261

Type and weight of Materials (not incorporated in the end product) (tonnes)*

Baked anodes consumed in the

electrolysis process (t)

72,079

71,949

74,835

Direct

measurement

Internal & External

sources

Coke

59,144

62,210

64,490

External supplier

Lime

60,121

59,388

61,459

Caustic soda

27,684

26,650

22,659

Tar

13,238

13,336

13,296

Lubricants

114

132

110

Aluminium fluoride

3,007

2,668

3,152

Internal sources or

production

Subtotal (2)

235,387

236,333

240,001

Type and weight of Packaging materials (tonnes)*

Pine planks

931

1,016

667

Estimation

External supplier

Polyester rings

20

15

28

Subtotal (3)

951

1,031

695

Total (1+2+3)

2,395,896

2,403,117

2,421,957

* From Non-Renewable Sources

In the

EPC Projects Sector

, METKA does not manage primary

natural resources, but instead manages semi-finished or fin-

ished products, according to the detailed plans/drawings and

procedures for each project, which specify with great accuracy

each material to be used, its manufacturing method and its exact

position and operation. These plans/drawings and procedures of

the company conform to the latest developments in the respec-

tive fields of expertise. They involve the use of complex materi-

als/products such as turbines, power generators, pumps etc. for

incorporation in its products/projects, together with more simple

ones such as merchant bars (beams, pipes, steel plates, axles,

cast parts etc.) for manufacturing (cutting, welding, processing,

hardening) in its industrial facilities or in those of its subcontrac-

tors. The manufactured products are then transported to the cus-

tomer’s facility / construction site, where assembly/erection of the

final product (e.g. a power plant) takes place.

8.1 Environmental compliance

Compliance with the environmental legislation is a core priority of

MYTILINEOS Group and a major issue of equal importance with

issues such as personnel safety, quality, economic performance

and customer satisfaction, which the Group is managing in the

context of its efforts for continuous and responsible development.

This view, which also serves as the foundation of the Group’s en-

vironmental policy, aims to drive the continuous improvement of

its environmental performance and is based, first and foremost,

on the principle of adherence to the provisions of the law, as well

as to the agreements concluded and the voluntary commitments

made both by MYTILINEOS S.A. and by the Group’s subsidiaries.

To this end, the strict adherence to the applicable laws and to the

provisions of the regulatory framework, the implementation of a

regular environmental legislation review process and the appli-

cation of the environmental rules and regulations pertaining to

the Group’s activities, have resulted in the absence of any inci-

dents involving a deteriorating in the quality of the environment

during 2015.

G4-29

In October 2015, a non-routine inspection was conducted at

ALUMINIUM OF GREECE by an 11-strong team of inspectors

from the Hellenic Environmental Inspectorate. The inspection

took 3 full days and the inspectors visited almost all company

work areas. ALUMINIUM OF GREECE supplied all the relevant in-

formation and the necessary documents requested. According to

the inspectors, this inspection was one of the most extensive and

they were very positively impressed with the plant and with the

Environmental Management Plan it has in place. The inspection’s

findings will be announced in 2016.

8.2 Raw & Other Materials

G4-EN1

In 2015, approximately 2.18 million tonnes of raw materials (dry

basis) were used in the

Metallurgy & Mining sector

, posting a

marginal increase (by 0.7%) compared to 2014. Of this total quan-

tity, 85% relates to bauxite, which is the main raw material used

for the production of alumina and aluminium. A large portion of

the bauxite quantities required in the production process every

year comes from Greece and, more specifically, from the Mt

Helikon - Mt Parnassus - Mt Gkiona zone, where Greece’s most

important known bauxite deposits, estimated at around 100 mil-

lion tonnes, are located. The use of alternative raw materials, i.e.

byproducts or waste from other industries, which can reduce the

consumption of raw materials, is not applicable to aluminium

production.

G4-EN2

Group policy on responsible management of raw and other

materials:

Our Commitment

To identify the sources and assume the re-

sponsibility for the unavoidable impacts of

our operations on the natural environment

and to carry out concerted “green” actions or

programs to mitigate these impacts, coupled

with systematic monitoring and application

of the Group’s Environmental Measures and

Principles across all Group companies.

1

4

7

8

9

17

15

20

23

24

25

26

27

29

30

28

21

10

11

22

12

13

5

2

3

18

16

6

14

19

Environmental management

system and regulatory

compliance

All Group’s subsidiaries apply, certified ISO

14001, Environmental Management System

that is designed to minimize environmental

risks, adapt measures for preventing and

minimizing environmental accidents, train-

ing employees and enhance environmental

culture.

All Group companies comply with current

environmental legislation and are assessed

annually on their results. Their priority is

to implement streamlined policies of envi-

ronmental protection in order to achieve in-

creasingly better performance.

G4-14