30

31

MYTILINEOS HOLDINGS SUSTAINABILITY REPORT

2015

ALUMINIUM OF GREECE is implementing specific continuous im-

provement projects aimed at stabilising and reducing the levels of

these emissions. Additionally, the Group’s €30 million of planned

investments, which are currently in the implementation stage, in-

volving the construction of a new static furnace for alumina and

the modernisation of the equipment in the wider electrolysis area,

are expected to reduce CO

2

emissions.

In the

Energy Sector

, a key objective is to maintain the efficiency

rates achieved in the operation of the thermal power plants of Pro-

tergia, which are among the highest in Greece, making the best

possible use of natural gas as their primary fuel. To produce elec-

tricity, the Group’s thermal plants use natural gas. This is a fossil

fuel that has a lower carbon content compared to mineral fuels,

does not release SO

2

and particles, emits less NOx (mainly N0

2

) in

exhaust gases compared to the maximum allowed quantities un-

der the applicable laws, and produces less C0

2

(by 70%) compared

to lignite-fired plants.

The unceasing efforts of MYTILINEOS Group to integrate and pro-

mote environmental awareness aspects in its corporate culture are

implemented primarily through environmental training actions and

the use of innovative applications. In line with this approach, the

Group adopted the CO

2

NS/WEBSITE application, a tool awarded

for its contribution to addressing climate change, which concerns

the Calculation and Offsetting of the Total Carbon Footprint of the

Group’s corporate websites (the parent company’s and those of its

subsidiaries), in accordance with the CO

2

Neutral Seal innovative

certification method.

By endorsing this initiative, the Group establishes its websites as

Carbon Neutral by following a specific procedure. Initially, the total

greenhouse gas emissions from the operation of the websites are

calculated using an innovative methodology. The Group then pur-

chases an amount of high-quality carbon credits equivalent to the

emissions of its websites on an annual basis. With this purchase,

the Group helps support certified projects involving the use of re-

newable energy sources and the conservation of natural resourc-

es, currently in operation in various regions around the globe.

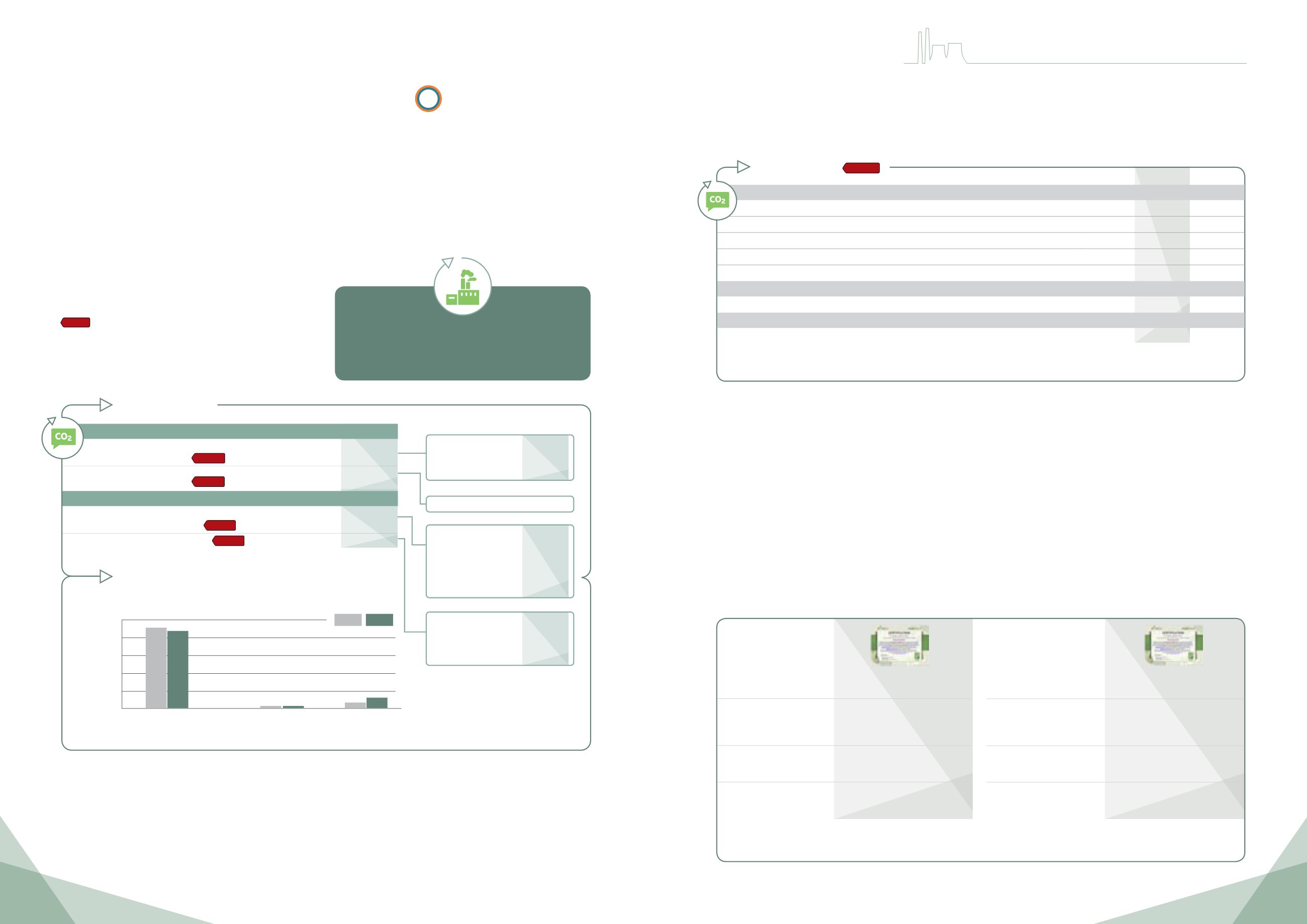

Carbon Neutral Certificate*

Carbon impact from

the electricity of the

server and internet

infrastructure

102.0 kg

CO

2

eq

The impact from the

electricity used by the

visitors

18.0 kg

CO

2

eq

Total

120.0 kg

CO

2

eq

2014

2015

Change

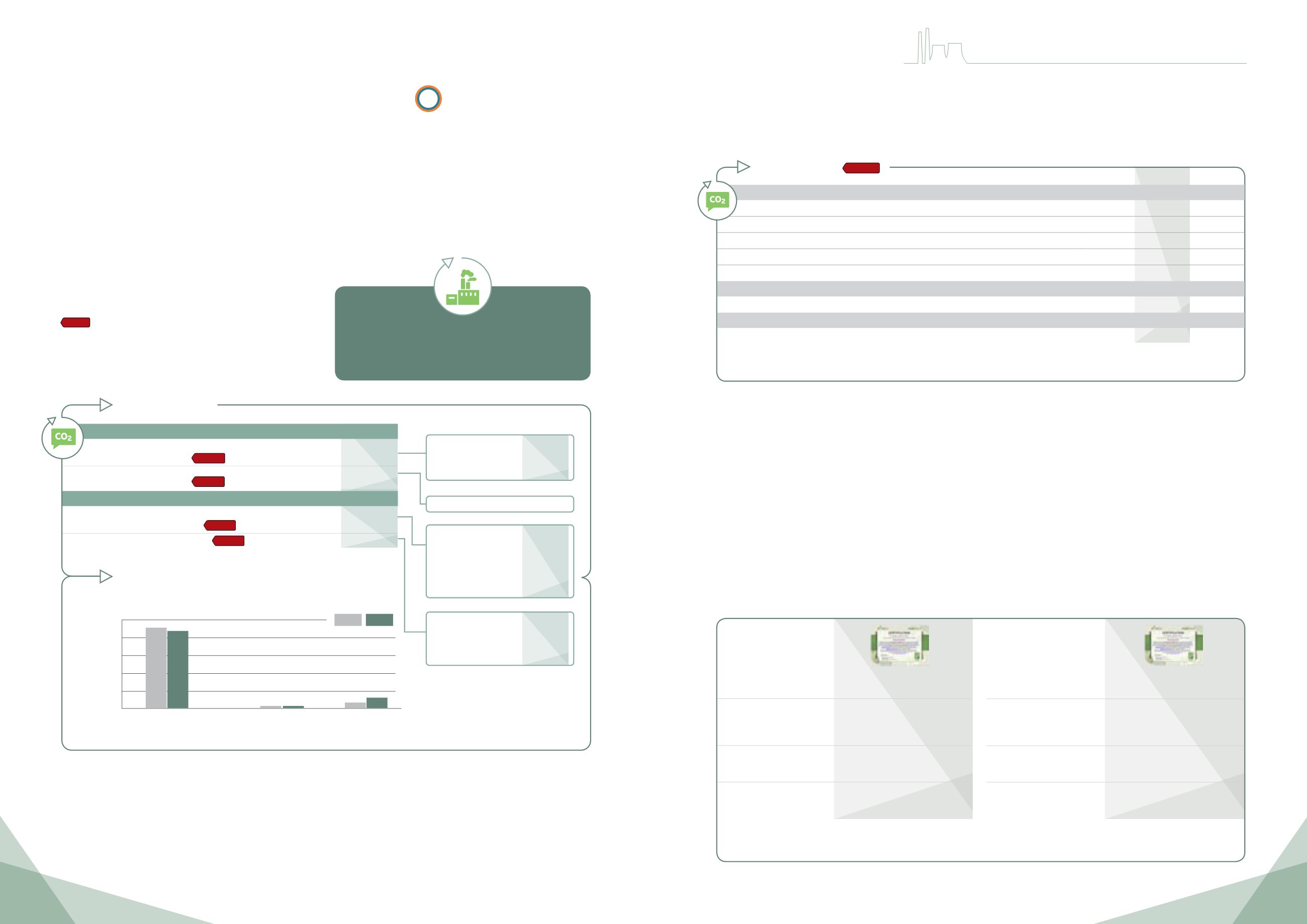

METALLURGY & MINING SECTOR

Specific emissions in Bauxite production (t CO

2

/t of bauxite produced)

0.06

0.012

100%

Specific emissions in Alumina production (t CO

2

/t of hydrated alumina produced)

-

0.76

-

Specific emissions in Aluminium production (t CO

2

/t of aluminium produced)

-

14.57

-

Fluorine emissions (t CO

2

/y)

213.8

243.2

13.7%

PFC’s emissions (t CO

2

/y)*

79,558.6

65,909.6

-17.1%

ENERGY SECTOR

Specific product consumption (tCO

2

/TJ of electricity produced)

96.89

93.85

-3.5%

EPC PROJECT SECTOR

Specific product consumption (tCO

2

/t of processed metal)

5.34

4.94

-7.5%

*Perfluorocarbons (CF

4

& C

2

F

6

) are gases that contribute significantly to global warming. To illustrate this, suffice to mention that 1 tonne of CF

4

is equivalent to

7,390 tonnes of CO

2

, while 1 tonne of C

2

F

6

is equivalent to 12,200 tonnes of CO

2

. These perfluorocarbons can be reduced by controlling the frequency and duration

of the anode effect during the electrolysis process.

Specific emissions

G4-EN18

Carbon Neutral Certificate*

Carbon impact from

the electricity of the

server and internet

infrastructure

169.5 kg

CO

2

eq

The impact from the

electricity used by the

visitors

50.5 kg

CO

2

eq

Total

220.0 kg

CO

2

eq

All Group subsidiaries apply electricity-saving practices, which

involve daily and weekly checks of the quality of production stag-

es, the mobilisation-sensitisation of the personnel involved, the

optimisation of parameters, the swift identification of problems

and the introduction of improvements to the equipment used.

To this end, in 2015 KORINTHOS POWER, a subsidiary of Pro-

tergia, managed to reduce its plant’s own consumption by 3.24

TJ through the conversion and refurbishment of equipment and

more specifically, by adding a new (smaller) closed-circuit cool-

ing system which operates when the Plant is on hold.

In addition, given the activity of the Group’s power plants, it is not

possible to save primary energy in any way other than by utilising

it in the best way possible, using the best methods available. In

this respect, the goal for Protergia is to maintain the productivity

of its natural gas fired thermal power plants within the high-effi-

ciency end of the output curve and to ensure maximum reliability

and availability regarding their operation throughout the year.

G4-EN6

This is mainly due to the increase in aluminium production and

also to the increase in the production of electricity by the thermal

plans of Protergia.

In the

Metallurgy & Mining sector

, specific targets have been set

that help stabilise CO

2

emissions during aluminium production.

More specifically, primary-cast aluminium is obtained by alumina

through electrolysis. This process produces carbon dioxide, fluo-

rine emissions and perfluorocarbons (PFCs).

*The volume of Scope 3 emissions refers only

to METKA, with the exception of business

travel, which also includes the performance of

Protergia.

2014

2015

3.793.740,7

4.610.939

ΣΥΝΟΛΟ

4.058.973,6

1,489,015.2

2,304,725.5

2013

2,353,548

2,257,391

Other indirect greenhouse

gas emissions (Scope 3)*

Other significant emissions

2,868.6

4,238.2

1,999.2

5,360.6

1,619.5

4,998.1

2014

2015

100%

80%

91,8%

88,3%

11,5%

8,0%

0,2%

0,2%

60%

40%

20%

0%

Percentage of emissions (Scope 1 & Scope 2)

by activity sector

Emissions (t CO

2

eq)

Direct greenhouse gas

emissions (Scope 1)

Indirect greenhouse gas

emissions (Scope 2)

Fuels (CO

2

)

Processes (CO

2

)

Processes (PFCs)

Transport (CO

2

)

1,307,557.8

286,712.9

65,909.6

6,191.0

717.3

694.2

208.0

3,780.2

906.6

243.2

68.1

Consumption of electricity (CO

2

)

SOx

NΟx

Fluorine

Particles

Transportation

of products (CO

2

)

Business travel (CO

2

)

Personnel travel

to/from work (CO

2

)

G4-EN15

G4-EN16

G4-EN17

G4-EN21

1,666,371.3

2,392,602.3

Metallurgy &

Moning Sector

EPC Project

Sector

Energy

Sector

Group policy on adapting to climate change:

8.4 Emissions

The MYTILINEOS Group activity sectors, and especially the Metal-

lurgy & Mining sector, generate carbon dioxide (CO

2

) emissions.

These are distinguished into direct (Scope 1) and indirect (Scope

2) CO

2

emissions. Direct emissions result primarily from the alu-

minium production process (consumption of fuels and chemical

processing as part of the production process) and secondarily

from electricity production (consumption of natural gas), with in-

direct emissions corresponding primarily to the consumption of

electricity. In 2015, total direct and indirect emissions stood at 4.06

million tonnes, up 7% compared to 2014.

1

4

7

8

9

17

15

20

23

24

25

26

27

29

30

28

21

10

11

22

12

13

5

2

3

18

16

6

14

19

*A carbon neutral website is one for which the total greenhouse gas emissions from its operation have been calculated in real time (using an

innovative methodology) and have been offset through an equivalent amount of carbon credits, thus making the website’s operation climate-

and environment-friendly.