In the Construction & EPC Projects sector, our

activities concern mainly the manufacturing

and assembly of products, i.e. they involve the

use of complex materials/products such as tur-

bines, power generators, pumps etc., togeth-

er with more simple ones such as merchant bars

(beams, pipes, steel plates, axles, cast parts

etc.) for manufacturing (cutting, welding,

processing, hardening) in our industrial facil-

ities or in those of our subcontractors. The

manufactured products are then transported

to the customer’s facility / construction site,

where assembly/erection of the final product

(e.g. a power plant) takes place.

Our subsidiary METKA S.A. does not manage

primary natural resources, but instead manages

semi-finished or finished products, in accor-

dance with the detailed plans/drawings and

procedures for each project, which specify with

great accuracy each material which will be

used, its manufacturing method and its exact

position and operation. These plans/drawings

and procedures represent the company’s

know-how, which conforms to the latest de-

velopments in the respective fields of expert-

ise.

The percentage of the use of recycled mate-

rials in the implementation of projects during

2013 stood at 28.8%.

**

Additionally, our requests for proposals and

contracts with suppliers of materials and

equipment contain a specific clause regarding

their compliance with the requirements of the

ISO-14000 International Standard, specifically

regarding the prohibition of using environ-

mentally hazardous materials and the obli-

gation to use recyclable materials to the high-

est possible degree.

In the Energy sector, the raw material used in

our thermal power plants is natural gas,

which cannot be recycled and is a non-re-

newable material.

22

I

n the Metallurgy & Mining sector, during

2013 we used more than 2.1 million tons

of raw materials (on dry basis) to produce

aluminium. Recycled materials or alternative

raw materials (by-products and waste dis-

posals from other industries) are not used for

the time being in the aluminium production

process to lower the consumption of raw ma-

terials.

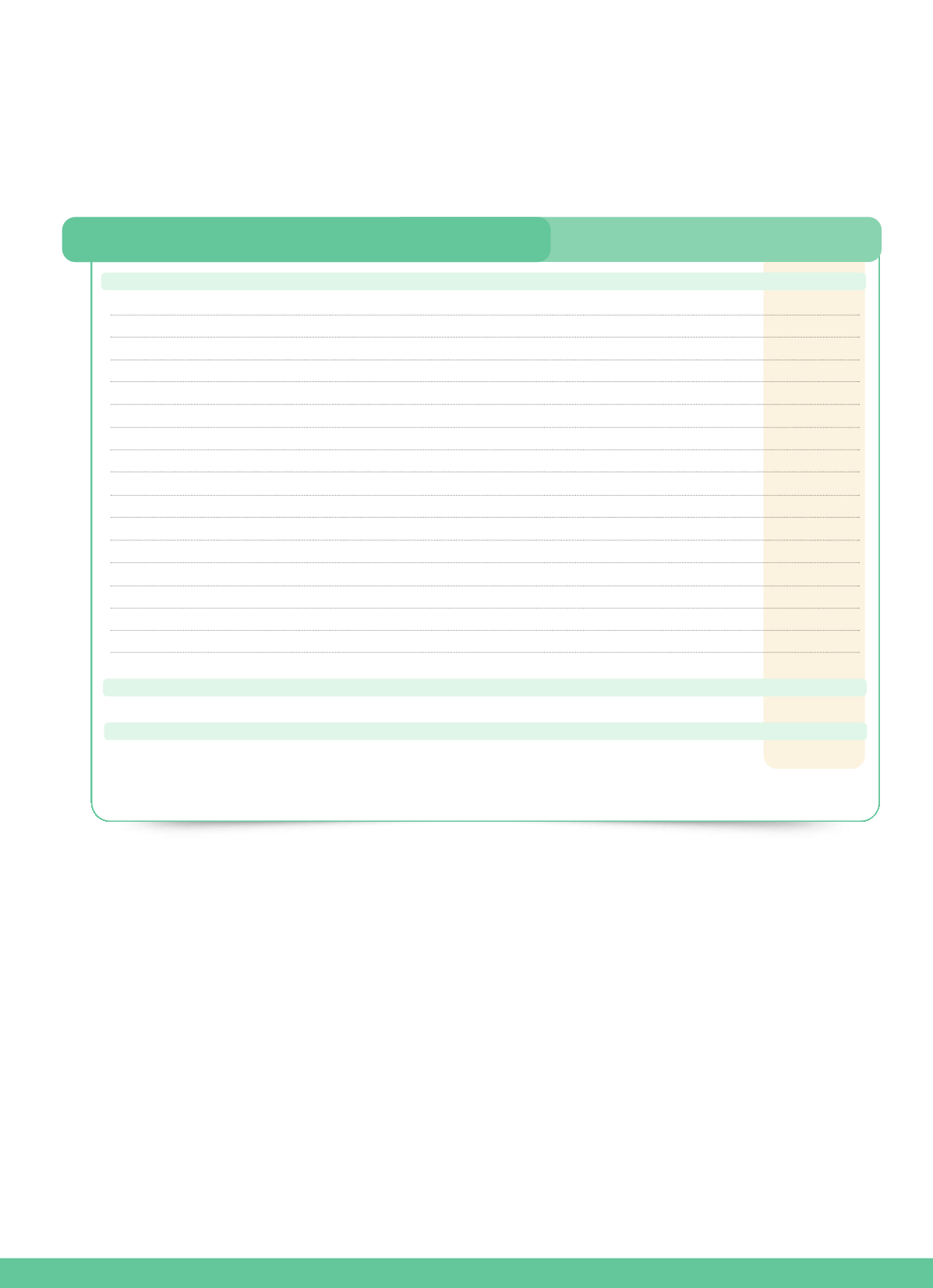

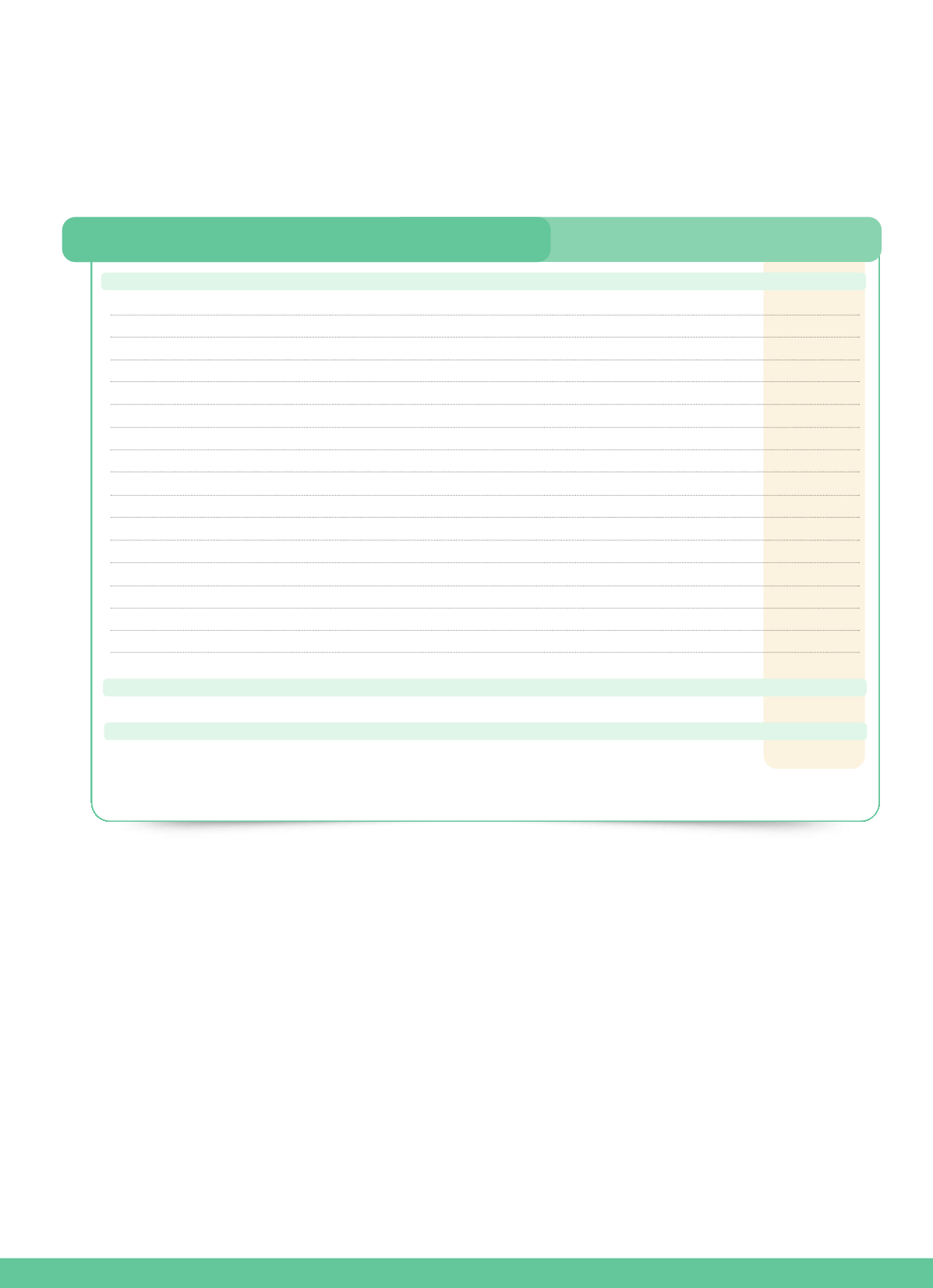

METALLURGY & MINING SECTOR

Materials used, by weight or volume

Raw materials

Bauxite (t)

Limestone (t)

*

Anhydrous alumina for electrolysis (t)

Other metals from third parties (t)

Alloys (t)

Materials used but not incorporated in the end product

Caustic soda (new soda) (t)

Calcium oxide (lime) (t)

Lubricants (t)

Tar (t)

Coke (t)

Aluminium fluoride (t)

Baked anodes consumed in the electrolysis process (t)

Packaging materials

Pine planks (t)

Polyester rings (t)

Total weight of non-renewable materials used

Raw materials (t)

Total weight of directly used materials

Bauxite & Alumina (t)

2011

1,816,912

118,579

317,082

3,194

145

26,293

66,760

102

14,578

65,336

2,644

68,972

1,028

27

2,255,912

2,133,994

2012

1,745,941

54,363

317,912

292

158

25,451

66,397

117

15,000

75,039

3,182

70,193

919

15

2,118,666

2,063,853

2013

1,830,398

0

326,985

322

1.853

27,684

60,121

114

13,238

59,144

3,007

72,079

931

20

2,159,559

2,157383

*

The lime furnace did not operate during 2013.The quantity required for the production process was purchased from an external supplier.

**

Of the 320 tons of total weight of materials used, steel in the form of plates or merchant bars accounts for approximately 230 tons. Around 40% of the

EU’s total steel production comes from electric arc furnaces, in which steel is produced from 100% recycled raw material (scrap). Thus, the recycled steel used

in our projects is estimated at 92 tons (40% of 230 tons).

5.3 MANAGEMENT OF RAW & OTHER MATERIALS