D

uring 2013, we recorded a total of 38 in-

cidents in the Metallurgy & Mining sec-

tor involving spillage in the soil of lubricants

weighing nearly 4.2 tons, a quantity increased

by 20% from the corresponding one for

2012. These spills were primarily due to

breakdowns in machinery caused during the

mining process in the tunnels of underground

quarries. By way of clarification, it should be

pointed out that these spills are an unavoid-

able part of the mining process, as they are

caused mainly by wear and tear of lubricant

pipes and by damages to machinery by falling

rocks. In addressing this problem, our subsidiary

DELPHI-DISTOMON S.A. is taking steps to en-

sure the following:

(1) The purchase of supplies (lubricant pipes)

with the best quality available in the market,

to secure the maximum possible strength.

(2) The implementation, on an annual basis, of

special-purpose seminars to raise personnel

awareness regarding the need to report and log

such incidents, in line with the company’s pol-

icy on the protection of the environment, as

well as regarding the use of specific techniques

to contain the extent of the spills in the soil.

(3) The existence of immediate response

methods for dealing with such incidents, col-

lecting carefully the quantity of contaminat-

ed soil and forwarding it to the hazardous

waste area for appropriate handling.

Overall, no high or medium severity environ-

mental pollution incidents occurred and no in-

cidents were reported involving the spillage of

hazardous substances to the environment by

any of the other Group companies.

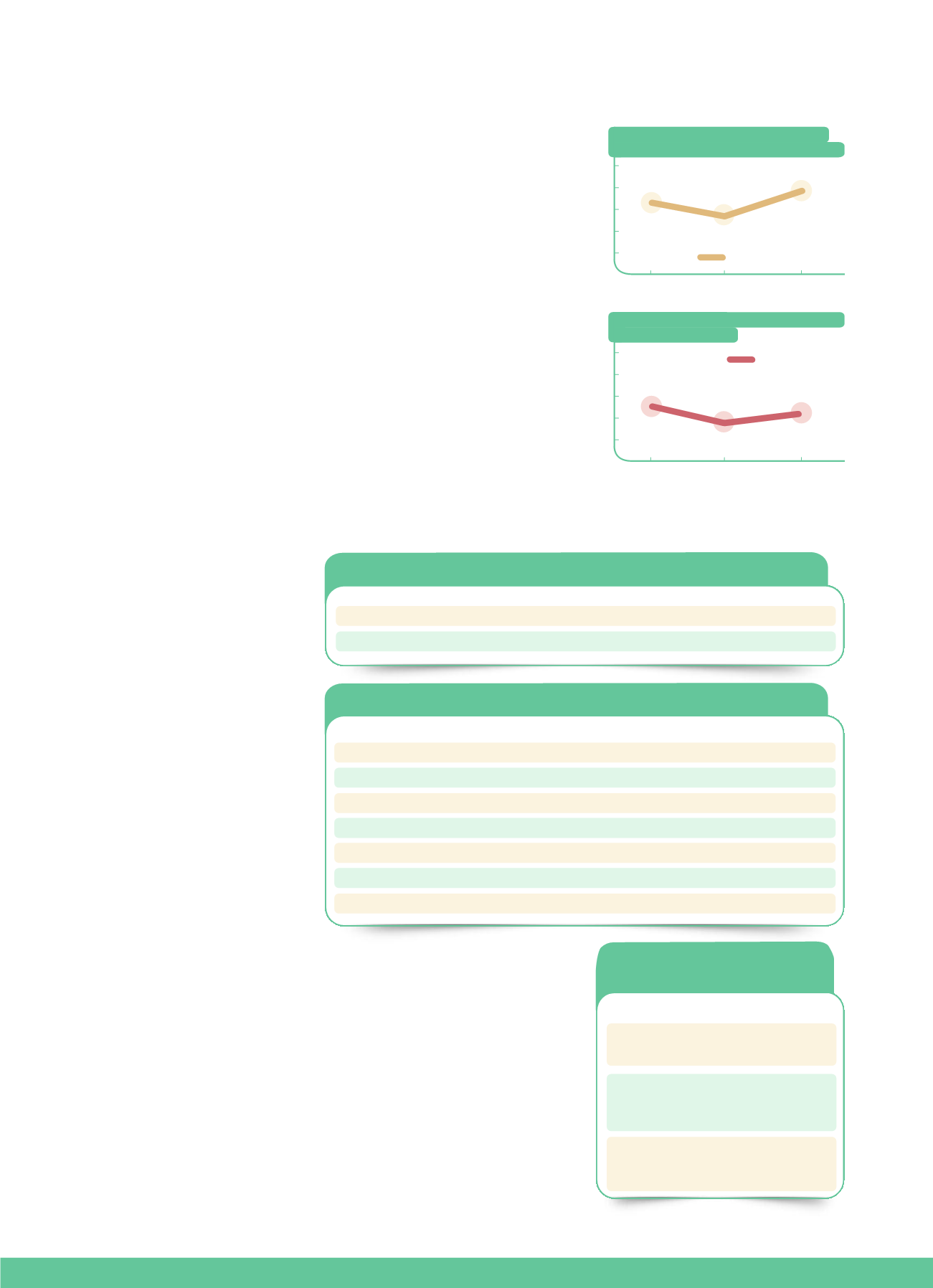

27

50

40

30

20

10

0

2011

2012

2013

33

27

38

T

he total quantity of waste from our ac-

tivities during 2013 stood at 923,358

tons, slightly less (by 3%) than the corre-

sponding quantity for 2012. Of this total

quantity, 96% comes from the Metallurgy &

Mining sector and only 4% from the Group's

other activities. In terms of category, haz-

ardous waste were reduced by 5.8% and

non-hazardous ones by 2.7%.

Waste recycling and recovery is followed in all

our subsidiaries, by means of specialised pro-

cedures applied in the stages of production, man-

agement, collection, treatment/recovery and dis-

posal of the respective waste. Where waste can-

not be recycled internally, this is done trough

collective waste management systems or li-

censed waste contractors. In 2014, the total vol-

ume of waste forwarded for recycling stood at

44,211 tons, posting an impressive increase from

2012. This quantity involved mainly industrial

waste such as bauxite residues, foundry skim-

mings etc., as well as various types of materi-

als collected, including metal scrap (e.g. iron and

steel), vehicle batteries, used lubricants, elec-

trical and electronic equipment, paper, carton,

wooden pallets, home batteries and toner car-

tridges from printers and photocopiers.

When disposal is in controlled landfills, all haz-

ardous waste and aggregates and all non-haz-

ardous waste, disposed of in the Controlled

Landfill for Hazardous Waste and in the Con-

trolled Landfill for Non-Hazardous Waste, re-

spectively, of ALUMINIUM S.A. are declared,

including bauxite residues, which represent

nearly 90% of all waste produced.

The mining process and the production of

aluminium generate the main volume of the

Group's waste, which represents one of the

biggest challenges facing its Metallurgy &

Mining sector. Waste consists mainly of

bauxite residues, which result from the solu-

bilisation of the alumina contained in the baux-

ite. In order to manage efficiently this waste,

in the last years we have carried out sub-

stantial investments focusing on effective

ways for the disposal of this waste on land,

in a Group-owned area, as well as on the avail-

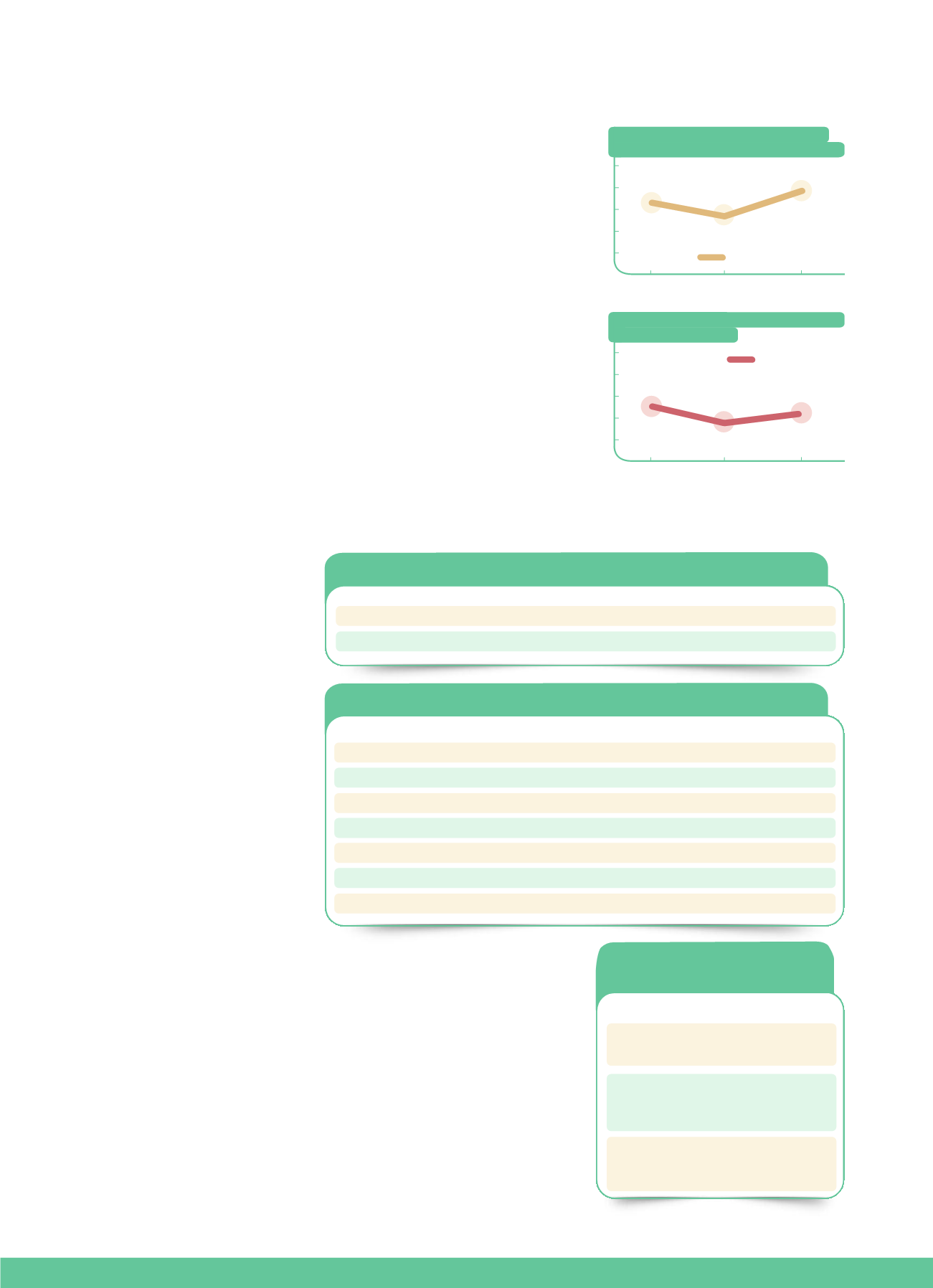

5.8 MANAGEMENT OF SOLID AND LIQUID WASTE

5.7 SIGNIFICANT SPILLS

2011

19,769.6

982,078.6

Hazardous waste

Non-hazardous waste

2012

20,952.6

929,231.8

2013

19,175.2

904,183.2

Rocks & stones (waste

from underground quarries)

Residues from

treatment processes

(bauxite residues)

Mud (wastewater

treatment)

2011

3,182.1

88,430.3

5.0

681,077.9

16,430.3

8.0

Recycling / Recovery

Reuse / Reutilisation

Incineration (or use as fuel)

Controlled Landfills for Non-Hazardous Waste

Controlled Landfills for Hazardous Waste

Uncontrolled Landfills (household waste)

Storage on-site

2012

4,957.7

28,295.2

28.5

832,028.0

16,997.3

6.0

66,100.0

2013

44,211.8

28,295.2

15.0

808,960.0

19,020.0

6.0

26,211.0

2013

267,479

807,272.95

86.04

WASTE QUANTITIES FROM THE GROUP'S ACTIVITIES, BY CATEGORY (TN)

WASTE SPECIFIC TO THE

METALLURGY & MINING

SECTOR (TN)

NUMBER OF INCIDENTS INVOLVING

SPILLAGE OF LUBRICANTS IN THE SOIL

10

8

6

4

2

0

2011

2012

2013

5

3.5

4.2

QUANTITY OF LUBRICANT SPILLAGE

IN NTHE SOIL (tn)

Number of spillage incidents

Spillage quantity (tn)

WASTE QUANTITIES BY DISPOSAL METHOD (TN)